Recently, the 8th China-Eurasia Expo kicked off at the Xinjiang International Convention and Exhibition Center, built by CSCEC.

The Expo, spanning three days, covers an indoor and outdoor exhibition area of 160,000 square meters and features participation from over 1,900 enterprises and institutions from 50 countries, regions, and international organizations.

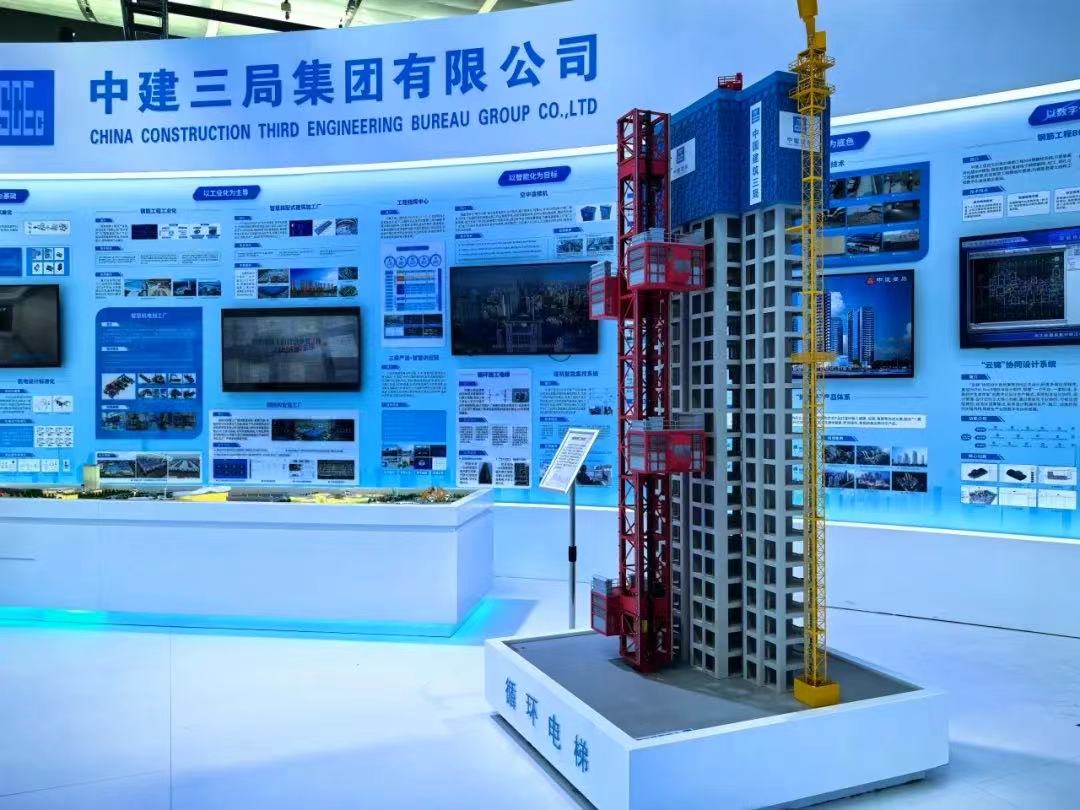

CSCEC's exhibition showcased its independently developed intelligent construction achievements, including an engineering command center, smart management platform, and industry-first innovations such as the lightweight skyscraper-building machine, intelligent tower crane control system, and cyclic construction elevator. These exhibits highlighted CSCEC's technological expertise in smart construction to the global audience.

Lightweight skyscraper-building machine

As an integrated intelligent and enclosed operation platform combining construction equipment and storage yard, the lightweight building machine boasts a maximum lifting speed of 9 seconds per floor. It reduces the time required to complete one floor to 4-5 days, accelerating the construction process by approximately 30% compared to traditional methods.

Intelligent tower crane control system

This system revolutionizes the traditional tower crane operation mode into a multi-tower control operation in a ground-based indoor environment. It allows flexible access and remote comprehensive control of multiple tower cranes and operation terminals, effectively reducing labor costs while ensuring collision-free safe operation through full-process digital monitoring.

Single-tower multi-cage cyclic construction elevator

By equipping a single guide rail frame with multiple construction elevator cages and an intelligent high-precision rotating rail-switching mechanism, the elevator achieves 180-degree rotation, enabling cyclic operation and significantly improving material transport efficiency.

Intelligent construction robots

The actual measurement robot scans the three-dimensional space with high precision and dead-angle-free 3D space scanning to ensure the accuracy and integrity of the data. AI automatic take-up technology is adopted to automatically extract and calculate the measurement data to improve the measurement efficiency. The leveling robot adopts intelligent laser leveling algorithm to ensure the flatness of construction. The troweling robot achieves autonomous navigation and to ensure even construction. The polishing robot adopts flywheel chassis technology combined with intelligent algorithm to achieve high precision polishing.